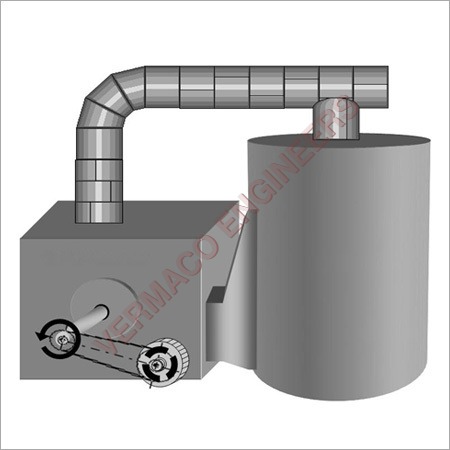

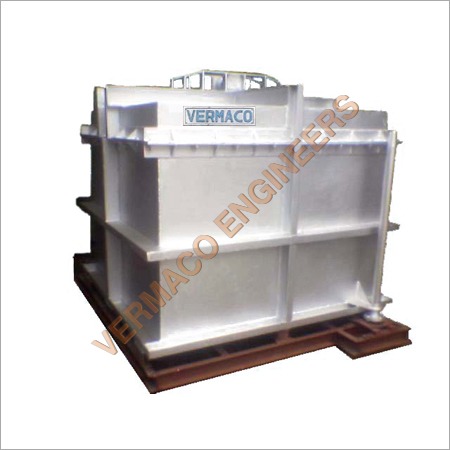

Heat Treatment Furnace Bell Type

Heat Treatment Furnace Bell Type Specification

- Feature

- Adopts energy efficient insulation, programmable temperature control, uniform heating

- Rating

- Industrial grade

- Condition

- New

- Usage

- Annealing, Normalizing, Hardening, Tempering

- Voltage

- 380V/415V AC, 3 Phase

- Size

- Custom sizes available from 1 m to 30 m

- Dimensions

- As per model specification

- Weight

- Varies from 1.2 T to 20 T (as per model)

- Application

- Metallurgical industries, automotive parts, forgings, heat treatment services

- Fuel Type

- Electric / Gas fired

- Capacity

- 500 kg to 20,000 kg per batch

About Heat Treatment Furnace Bell Type

With the aid of our dexterous professionals, we are able to manufacture, supply and export best quality Heat Treatment Furnace Bell Type. This furnace is suitable to be used at high temperatures and is safe to use. Our offered equipment is made by our precision engineers using quality raw components which are obtained from the authentic vendors of the market with the aid of advanced machines at contemporary technology. In order to provide safety and default free product to our variegated customers, this Heat Treatment Furnace Bell Type is also quality tested by our quality analysts keeping in mind the minutest intricacies.

Features:

-

Sturdy construction

-

Seamless finish

-

Efficient generation of heat

-

High performance

Advanced Temperature and Atmosphere Control

This bell-type furnace offers accurate digital PLC-based temperature management with integrated PID controllers. It operates across ambient to 1200C using either Type K or S thermocouples for high accuracy. Operators can select between nitrogen, argon, or air atmospheres to match specific metallurgical processes, ensuring repeatable results and material quality.

Robust Build and Energy Efficiency

Constructed from epoxy-coated sheet metal and insulated with double-layer fiber boards plus ceramic blankets, the furnace minimizes heat loss and maximizes energy efficiency. Hydraulic lift bell door and forced air cooling systems enhance operational safety and reduce cycle times, supporting heavy-duty industrial workloads efficiently.

FAQs of Heat Treatment Furnace Bell Type:

Q: How does the hydraulic bell-type door mechanism enhance furnace operation?

A: The hydraulic lift bell design allows for smooth, safe, and rapid opening and closing of the furnace chamber, facilitating easy loading and unloading of large or heavy components. This mechanism also improves sealing efficiency during heat treatment cycles, ensuring consistent atmospheric integrity.Q: What types of heating elements are used, and how do they benefit the process?

A: High-grade NiCr (Nickel-Chromium) or FeCrAl (Iron-Chromium-Aluminum) alloy elements are utilized for reliable, uniform heating up to 1200C. These alloys offer excellent longevity, oxidation resistance, and energy efficiency, which are critical for demanding heat treatment applications.Q: When should I use nitrogen or argon atmosphere in this furnace?

A: Nitrogen or argon atmospheres are used when oxidation or decarburization of metal components must be minimized during heat treatment. These inert gases create a controlled environment, essential for processes like annealing or hardening of critical metallurgical and automotive parts.Q: Where is this furnace typically installed or utilized?

A: This furnace is commonly installed in metallurgical industries, heat treatment service centers, automotive parts manufacturing, forging workshops, and other industrial sectors where batch processing of high-value metal components is required.Q: What is the process for selecting the right furnace model for my application?

A: To select an appropriate model, consider the batch capacity (range: 500 kg to 20,000 kg), internal volume (1 m to 30 m), required operating temperature, atmosphere controls, and specific application needs. Custom sizing and control options are available to match diverse industrial requirements.Q: How does the programmable PLC/PID control benefit users?

A: The integrated digital PLC with PID controller enables precise, programmable temperature cycles tailored to specific heat treatment processes. This ensures optimal repeatability, improved product quality, and reduced human error, streamlining batch production.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Heat Treatment Furnace Category

Heat Treatment Furnace Bottom Drop

Size : Customized or standard sizes available

Rating : Industrial Grade

Application : Hardening, Tempering, Annealing, Normalizing

Feature : Efficient insulation, Uniform heat distribution, PLC controlled

Usage : Other, Heat Treatment of Metal Components

Weight : Approx. 2500 Kg (varies by model)

Heat Treatment Furnace

Size : Customizable as per requirement

Rating : High Efficiency

Application : Heat Treatment Processes such as Annealing, Tempering, Hardening, Stress Relieving

Feature : Uniform Heat Distribution, Energy Efficient, Durable Construction

Usage : Other, Industrial/Foundry/Metallurgical

Weight : Varies by Model

Heat Treatment Furnace Door Type

Size : Customizable, as per client requirement

Rating : Industrial grade

Application : Hardening, Tempering, Annealing

Feature : High Durability, Uniform Heat Distribution, Easy Operation

Usage : Other, Heat Treatment Process

Weight : Varies as per size and specification

Send Inquiry

Send Inquiry