Heat Treatment Furnace

Heat Treatment Furnace Specification

- Rating

- High Efficiency

- Feature

- Uniform Heat Distribution, Energy Efficient, Durable Construction

- Condition

- New

- Usage

- Industrial/Foundry/Metallurgical

- Power

- Electric/Oil/Gas Fired Options

- Voltage

- 220V/380V/415V (As Per Order)

- Size

- Customizable as per requirement

- Dimensions

- Depends on Model/Capacity

- Weight

- Varies by Model

- Application

- Heat Treatment Processes such as Annealing, Tempering, Hardening, Stress Relieving

- Fuel Type

- Electricity/Oil/Gas

- Capacity

- Up to several tons (customized)

About Heat Treatment Furnace

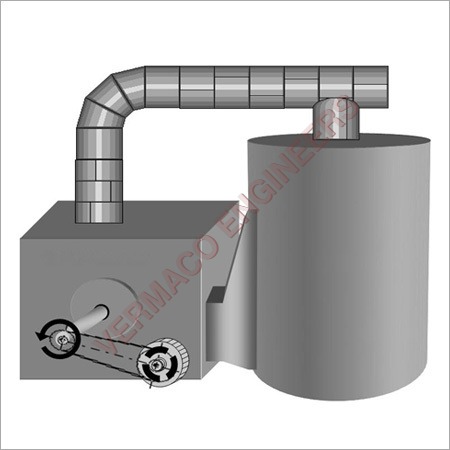

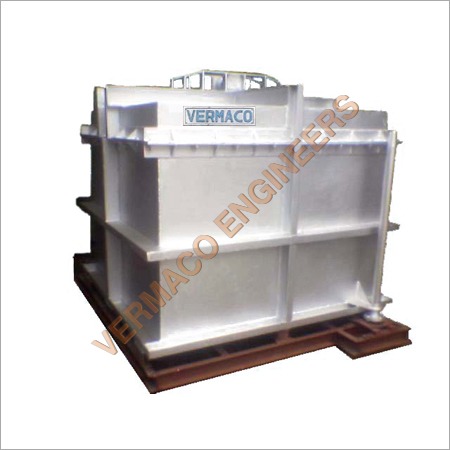

We are providing wide range of Heat Treatment Furnace includes Bell Type, Door Type, Botton Drop. These are used in several industrial applications. It has a strong construction that ensures high performance levels. Offered by us at market leading prices.Precision Engineering and Control

Equipped with advanced digital or PLC control systems, this heat treatment furnace delivers highly accurate temperature regulation. Operators can program cycles tailored to various heat treatment processes, such as annealing, tempering, or hardening, ensuring optimal results across a diverse range of industrial applications.

Durable Construction and Customization

Constructed from high-grade mild steel or stainless steel and reinforced with ceramic insulation, the chamber withstands rigorous conditions while maintaining energy efficiency. The furnace can be customized in terms of size, capacity, and fuel type, supporting electric, oil, or gas firing to meet unique process demands and spatial constraints.

Efficient Operation and Uniform Heat Distribution

High-efficiency ratings and uniform heat distribution ensure consistent material treatment and minimal energy loss. Automatic or manual load handling systems streamline workflow, while programmable cycle times optimize productivity for both small-scale and high-volume operations.

FAQs of Heat Treatment Furnace:

Q: How does the digital or PLC control system enhance the furnaces operation?

A: The digital or PLC control system allows for precise temperature setting and cycle programming, ensuring that every heat treatment processsuch as annealing, tempering, or hardeningis performed accurately and repeatably. This reduces the risk of human error and improves process efficiency.Q: What are the benefits of using Kanthal or Nichrome alloy heating elements?

A: Kanthal and Nichrome alloys provide excellent thermal stability, corrosion resistance, and longevity, making them ideal for sustained high-temperature operations. Their reliability helps maintain uniform heating and reduces maintenance downtime.Q: When should I choose manual versus automatic door operation or loading systems?

A: Manual systems are ideal for smaller-scale or less frequent heat treatment needs, offering simplicity and cost-effectiveness. Automatic systems, such as hydraulic or pneumatic doors and load handling, are recommended for larger capacities or high-volume operations to enhance safety, speed, and convenience.Q: Where can these heat treatment furnaces be installed or used?

A: These furnaces are designed for industrial settings, including foundries, metallurgical plants, and other facilities requiring precise heat treatment processes. Their customizable design ensures compatibility with various layouts and capacity requirements across India.Q: How is uniform heat distribution achieved inside the furnace chamber?

A: Uniform heat distribution is attained through the use of advanced heating elements and optimized chamber geometry, as well as ceramic insulation. These features work together to minimize temperature gradients throughout the chamber, leading to consistent material treatment.Q: What is the process for customizing furnace size and capacity?

A: Customization involves assessing the clients operational requirements, available space, intended material load, and preferred fuel type. The manufacturer collaborates with buyers to design and build furnaces that precisely match these parameters, ensuring effective and efficient installation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Heat Treatment Furnace Category

Heat Treatment Furnace Bell Type

Size : Custom sizes available from 1 m to 30 m

Application : Metallurgical industries, automotive parts, forgings, heat treatment services

Condition : New

Fuel Type : Electric / Gas fired

Dimensions : As per model specification

Rating : Industrial grade

Heat Treatment Furnace Bottom Drop

Size : Customized or standard sizes available

Application : Hardening, Tempering, Annealing, Normalizing

Condition : New

Fuel Type : Electric / Gas fired options

Dimensions : As per client requirement

Rating : Industrial Grade

Heat Treatment Furnace Door Type

Size : Customizable, as per client requirement

Application : Hardening, Tempering, Annealing

Condition : New

Fuel Type : Electricity / Oil / Gas

Dimensions : As per order specification

Rating : Industrial grade

Send Inquiry

Send Inquiry