Heat Treatment Furnace Bottom Drop

Heat Treatment Furnace Bottom Drop Specification

- Feature

- Efficient insulation, Uniform heat distribution, PLC controlled

- Rating

- Industrial Grade

- Condition

- New

- Usage

- Heat Treatment of Metal Components

- Power

- 30 kW (typical, customizable)

- Voltage

- 415V, 3 Phase

- Size

- Customized or standard sizes available

- Dimensions

- As per client requirement

- Weight

- Approx. 2500 Kg (varies by model)

- Application

- Hardening, Tempering, Annealing, Normalizing

- Fuel Type

- Electric / Gas fired options

- Capacity

- 500 Kg 3000 Kg

About Heat Treatment Furnace Bottom Drop

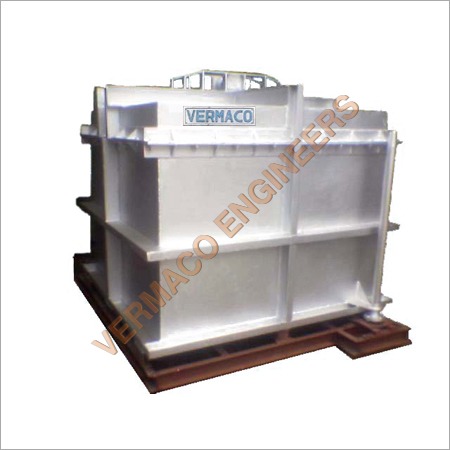

With the aid of our vast experience in this industry, we are able to manufacture, supply and export Heat Treatment Furnace Bottom Drop. This furnace is used in heat treatment of various metals such as aluminum. Our offered product is available with us in various specifications in order to fulfill the variegated needs of our customers. This heat treatment furnace is manufactured by our professionals using fine quality components which are obtained from the authentic vendors of the market with the aid of modern machines and high end technology. Our Heat Treatment Furnace Bottom Drop is widely acclaimed amongst our customers for:

- Robust construction

- Flawless finish

- Safe operation

- High heat generation

Precision Controls and Efficient Insulation

Equipped with a digital or PLC-based auto controller, this furnace ensures precision in temperature management with digital process indicators. The ceramic fiber or refractory brick insulation enhances thermal efficiency and supports uniform heat distribution, critical for consistent metallurgical results. The entire body, crafted in heavy duty mild steel and finished with heat resistant paint, offers durability for frequent industrial usage.

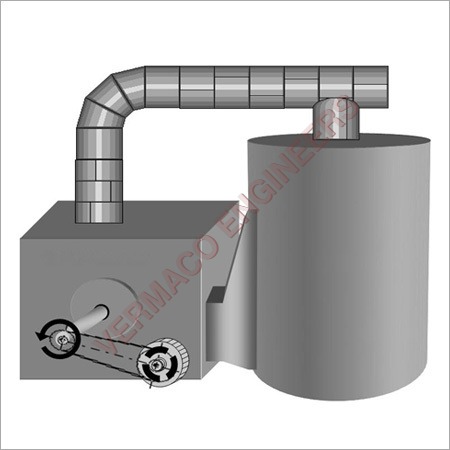

Versatile Loading and Safety Features

The bottom drop door, fitted with a lifting mechanism, allows safe and easy loading either manually or with an automatic hoist. These features, alongside the robust design and secure loading method, facilitate both small-batch and bulk operations. Whether for hardening, tempering, annealing, or normalizing, the system adapts to diverse heat treatment needs across standard or custom furnace sizes.

FAQs of Heat Treatment Furnace Bottom Drop:

Q: How does the bottom drop door mechanism improve the heat treatment process?

A: The bottom drop door with a lifting mechanism enables safer and more efficient loading and unloading of metal components. This design minimizes heat loss during operation and reduces thermal shock to the load, thereby improving process control and prolonging furnace life.Q: What materials are used for insulation and why are they important?

A: Ceramic fiber or refractory bricks are used for insulation in this furnace. These materials provide excellent thermal resistance, ensuring high energy efficiency and maintaining uniform temperatures, which are vital for achieving precise metallurgical properties during heat treatment.Q: When should I choose electric versus gas-fired options for this furnace?

A: Electric furnaces are often preferred for precise temperature control and cleaner operation, ideal in facilities where emissions must be minimized. Gas-fired options are suitable for larger loads or when rapid heating and cost-effectiveness for high-volume operations are required.Q: Where can this heat treatment furnace be installed and used?

A: This furnace is designed for use in industrial settings, such as metal component manufacturing plants, foundries, and heat treatment service providers. It can be customized to fit specific space requirements and integrated into various workflow setups across India and international markets.Q: What is the typical process for operating the furnace?

A: Operators load components manually or using an automatic hoist, set desired parameters on the digital or PLC interface, and monitor the process through the digital display. The system ensures even heating with tight temperature uniformity, while safety features maintain a controlled environment.Q: How does this furnace benefit metal heat treatment applications?

A: The furnaces high temperature uniformity (5C), efficient insulation, and precision control systems ensure that metal components undergo consistent hardening, tempering, annealing, or normalizing processesimproving final product strength, durability, and performance.Q: What sizes and capacities are available?

A: Both standard and customized sizes are offered to suit specific operational needs. Capacities range from 500 kg to 3000 kg, making the furnace suitable for a variety of batch sizes and industrial requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Heat Treatment Furnace Category

Heat Treatment Furnace Bell Type

Fuel Type : Electric / Gas fired

Condition : New

Usage : Other, Annealing, Normalizing, Hardening, Tempering

Application : Metallurgical industries, automotive parts, forgings, heat treatment services

Size : Custom sizes available from 1 m to 30 m

Feature : Adopts energy efficient insulation, programmable temperature control, uniform heating

Heat Treatment Furnace

Fuel Type : Electricity/Oil/Gas

Condition : New

Usage : Other, Industrial/Foundry/Metallurgical

Application : Heat Treatment Processes such as Annealing, Tempering, Hardening, Stress Relieving

Size : Customizable as per requirement

Feature : Uniform Heat Distribution, Energy Efficient, Durable Construction

Heat Treatment Furnace Door Type

Fuel Type : Electricity / Oil / Gas

Condition : New

Usage : Other, Heat Treatment Process

Application : Hardening, Tempering, Annealing

Size : Customizable, as per client requirement

Feature : High Durability, Uniform Heat Distribution, Easy Operation

Send Inquiry

Send Inquiry